Vehicle Soft Trim and Insulation

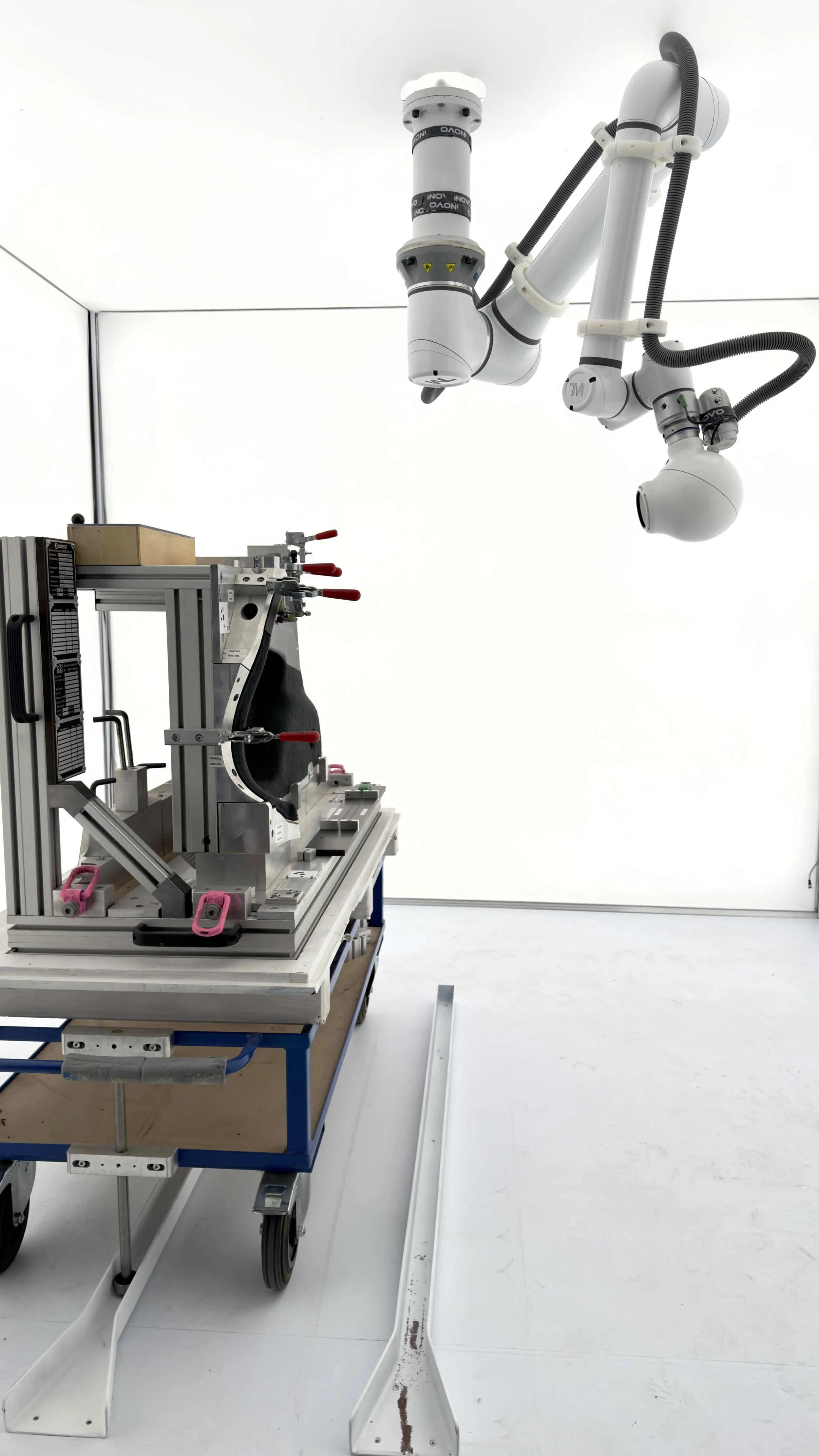

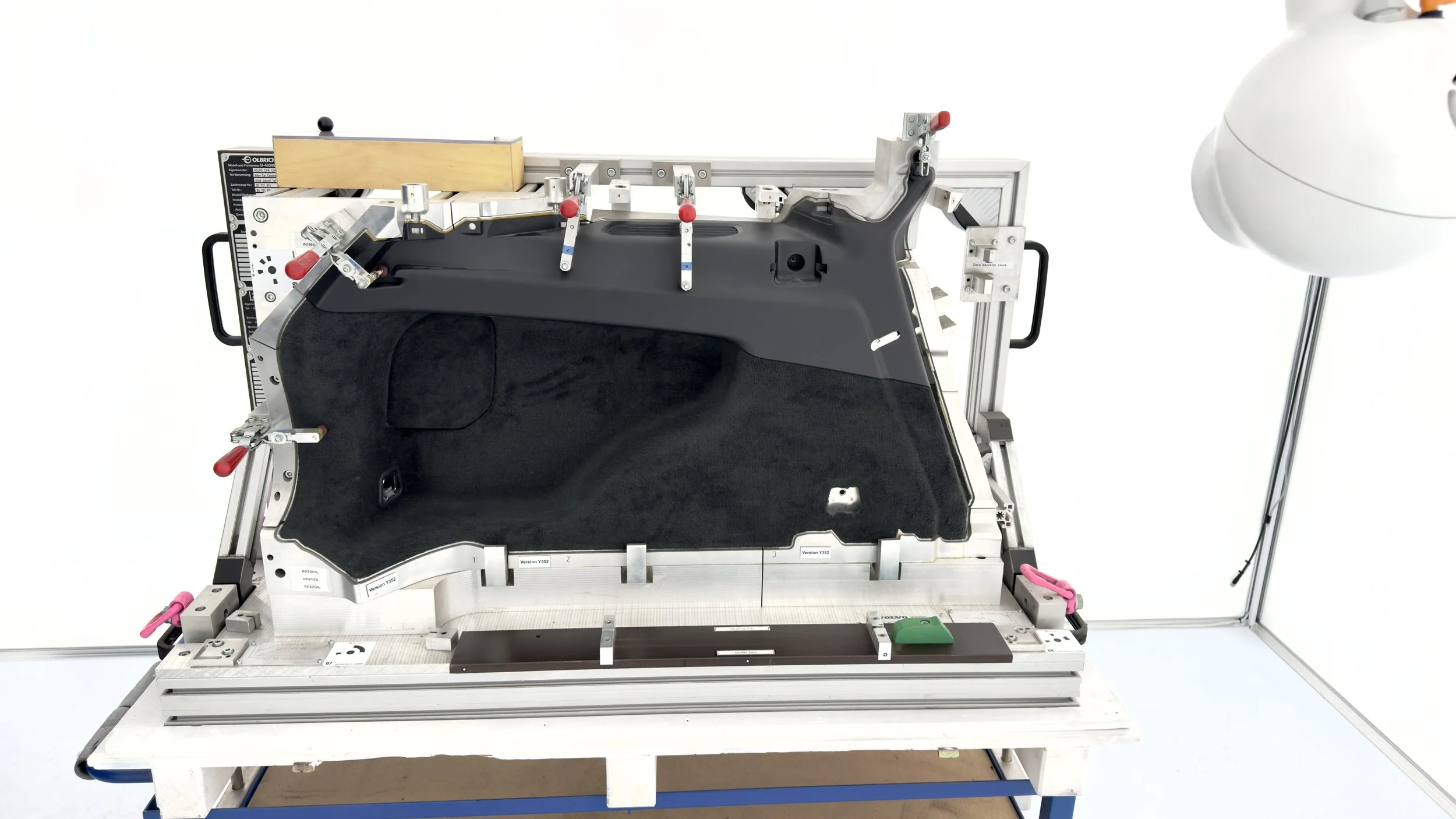

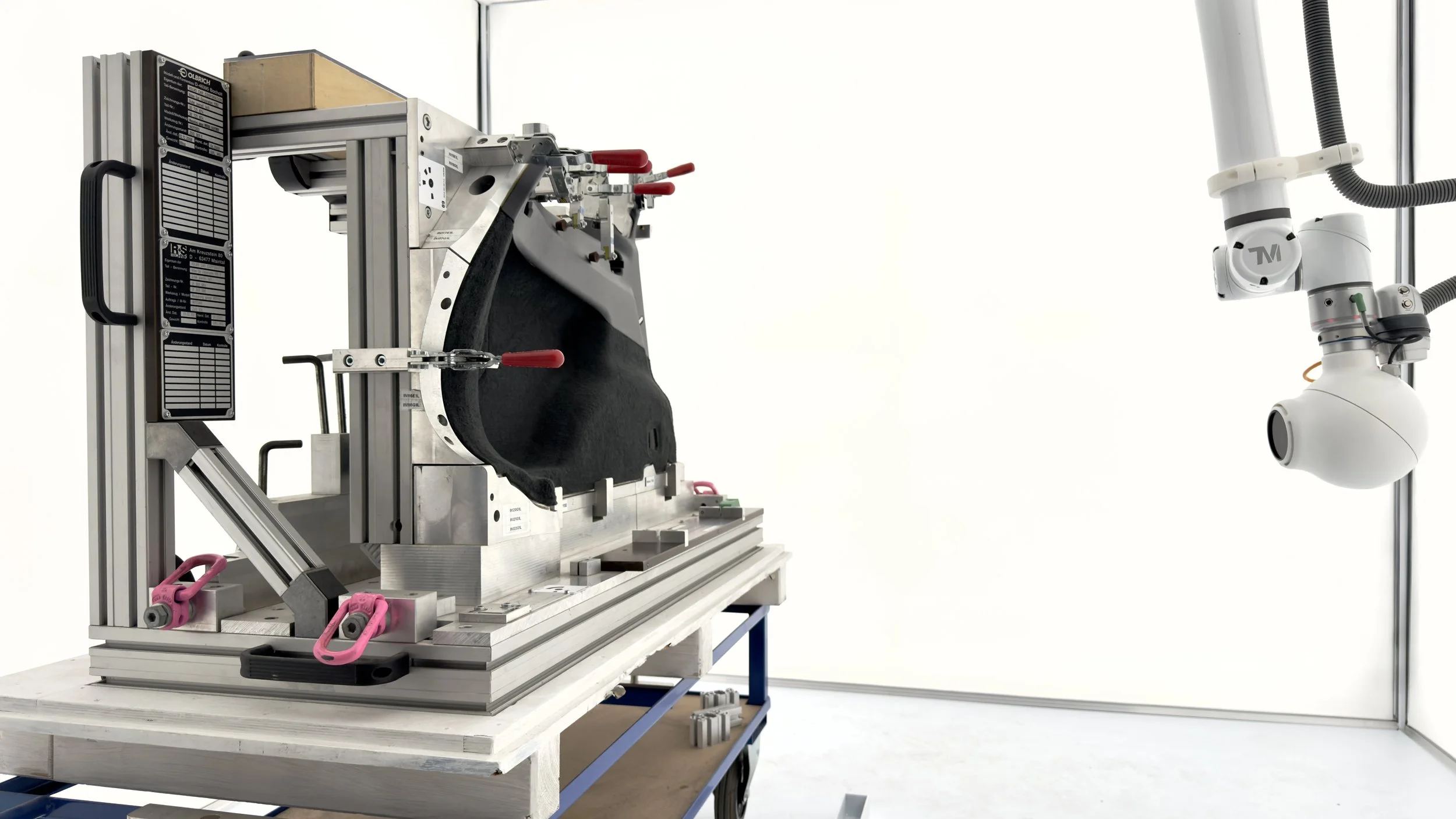

We deliver automated, non-contact inspection for automotive interiors. Carpets, dash insulators, trims, and liners are measured with precision to meet strict OEM GD&T requirements. Even small deviations in profile, flatness, or hole position are detected before assembly.

Capture interior geometry with unprecedented clarity.

Interior components can be soft, fibrous, or multi-layered making traditional measurement unreliable. Large panels with freeform geometry and multiple cutouts are automatically scanned, with every feature referenced to defined datums for accurate, repeatable measurement.

GigaScan’s advanced software guides operators through the inspection process. Non-contact

scanning and automated measurement mean consistent, precise results without the

need for manual fixturing or probing.

Automated measurement of key datums and features

The system measures surface profiles, hole positions, edge locations, and other critical GD&T characteristics. Inline inspection ensures every part complies with tolerance requirements, supporting repeatable quality across large production volumes.

Take control of your production line. Early verification of GD&T compliance reduces assembly issues, rework, and line stoppages. Continuous data enables faster root-cause analysis and tighter process control.

Supporting PPAP and OEM requirements

GigaScan generates objective, traceable dimensional data to simplify PPAP submissions and OEM reporting. Consistent measurement increases confidence in capability studies and reduces approval back-and-forth.

GigaScan inspects vehicle interior trims across all types.

Luggage Side

Floor Carpet

Dash Insulation Pad

Headliner

Reducing variation in series production

GigaScan’s advanced software guides operators through the inspection process. Non-contact scanning and automated measurement mean consistent, precise results without the need for manual fixturing or probing.

Borgers Nord AB has the GigaScan system installed and actively

uses it as part of their production process.

The system supports quality control and inspection within daily manufacturing operations, demonstrating GigaScan’s reliability in an industrial production environment.