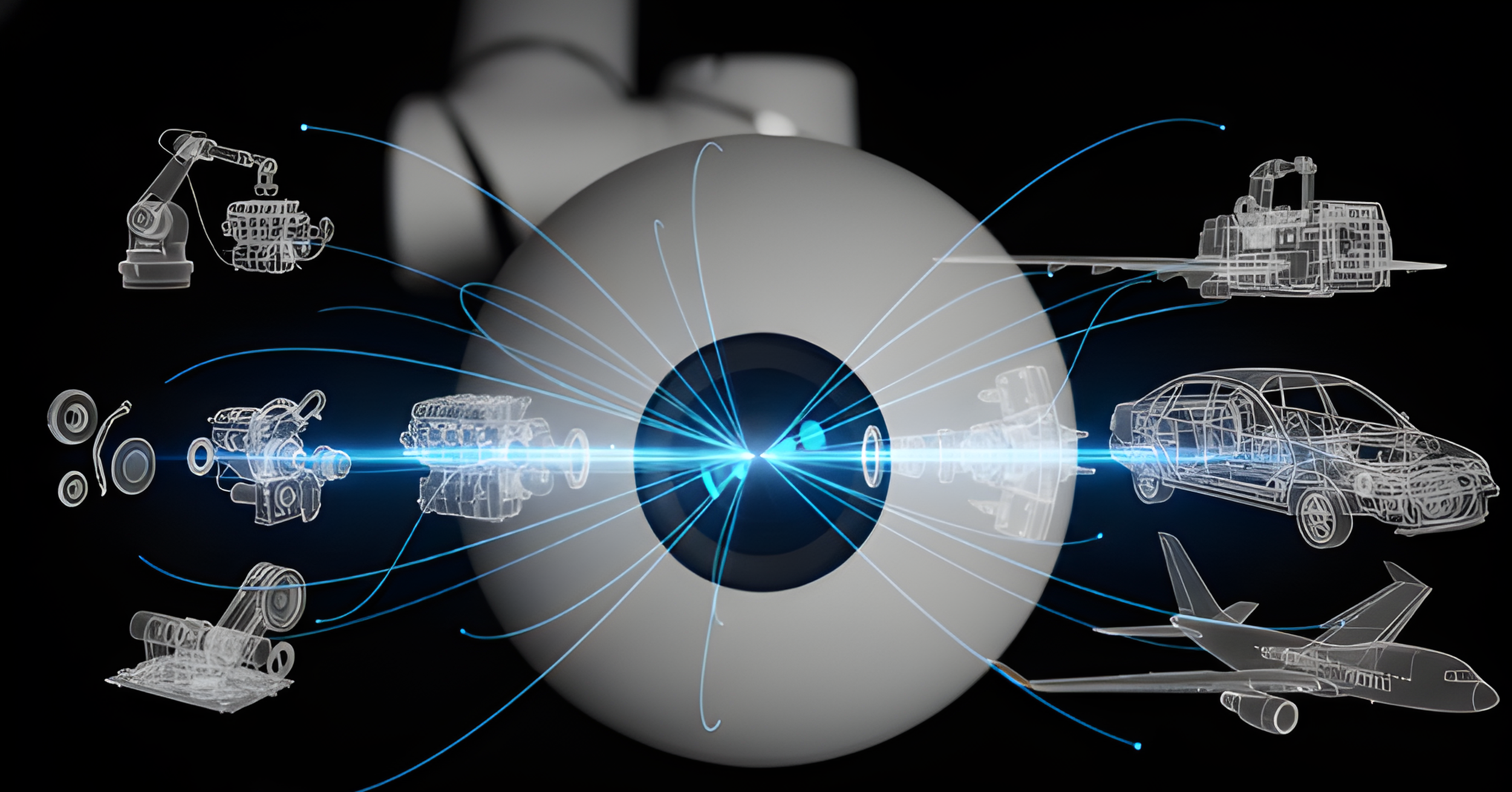

Our Vision: Your Precision.

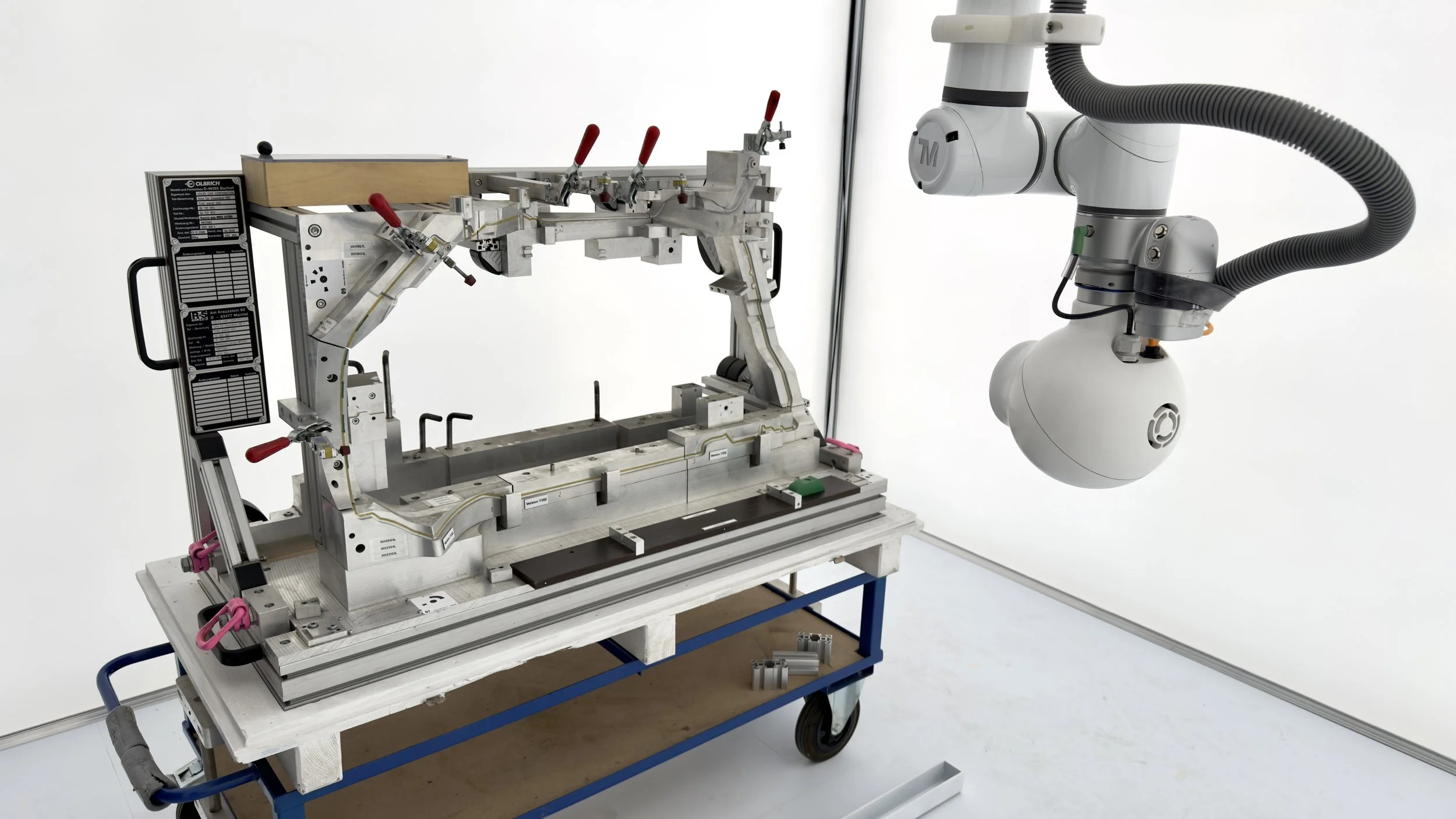

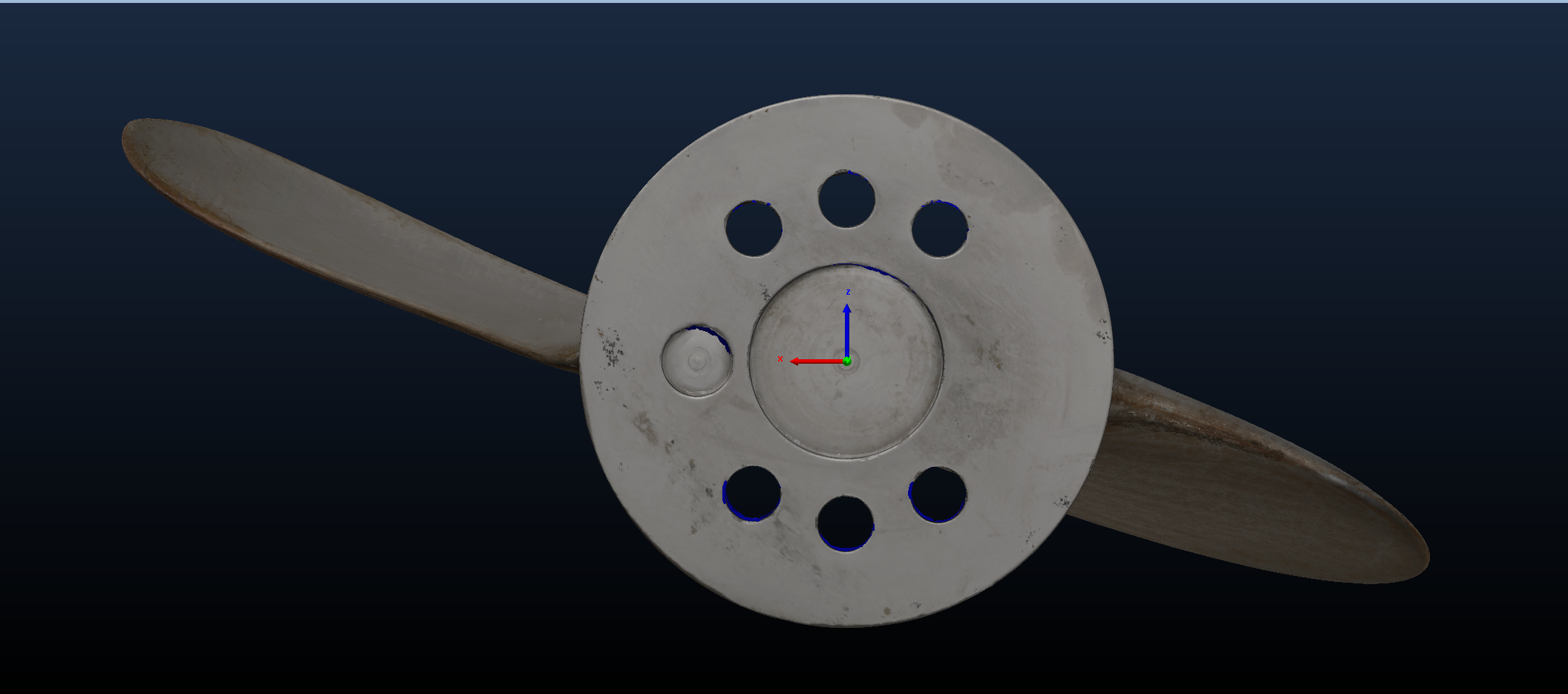

GigaScan brings lab-grade measurement directly to your production line with no delays, no spray, and no doubts.

Why Standard Inspections Can’t Match GigaScan

-

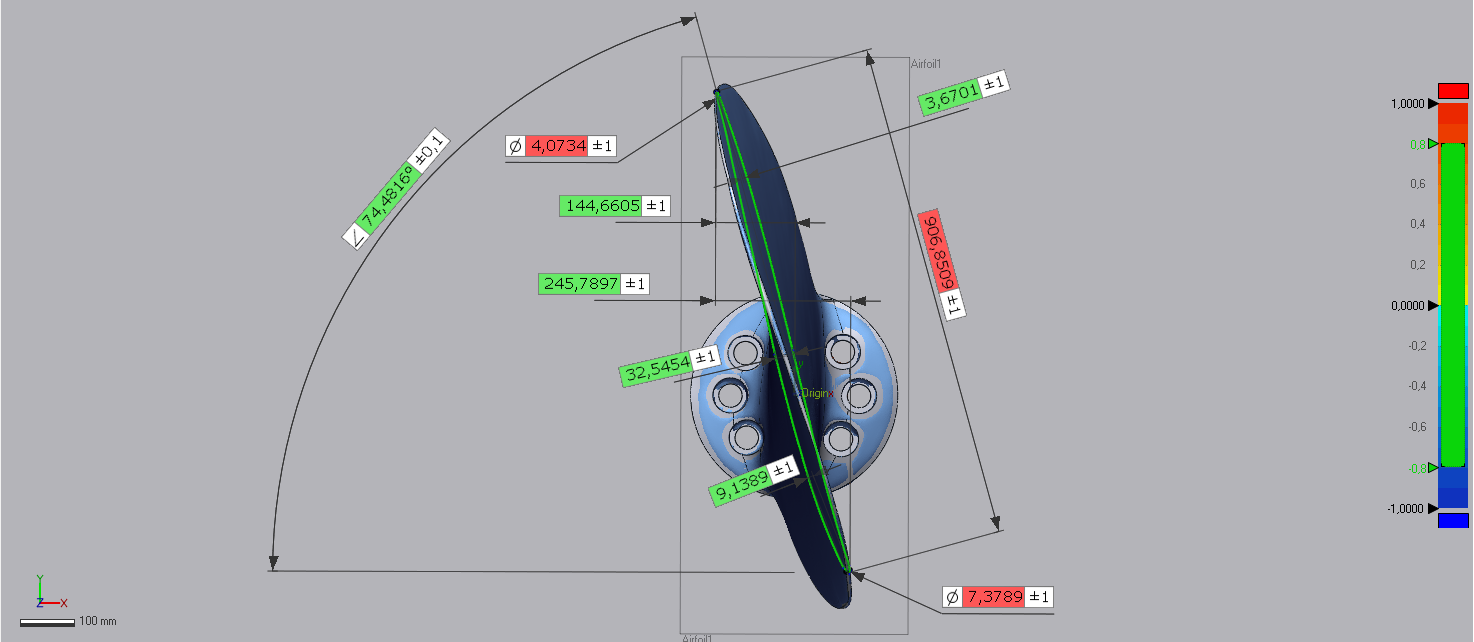

Measurements are calibrated in accordance with ISO 10360-13:2021 requirements.

-

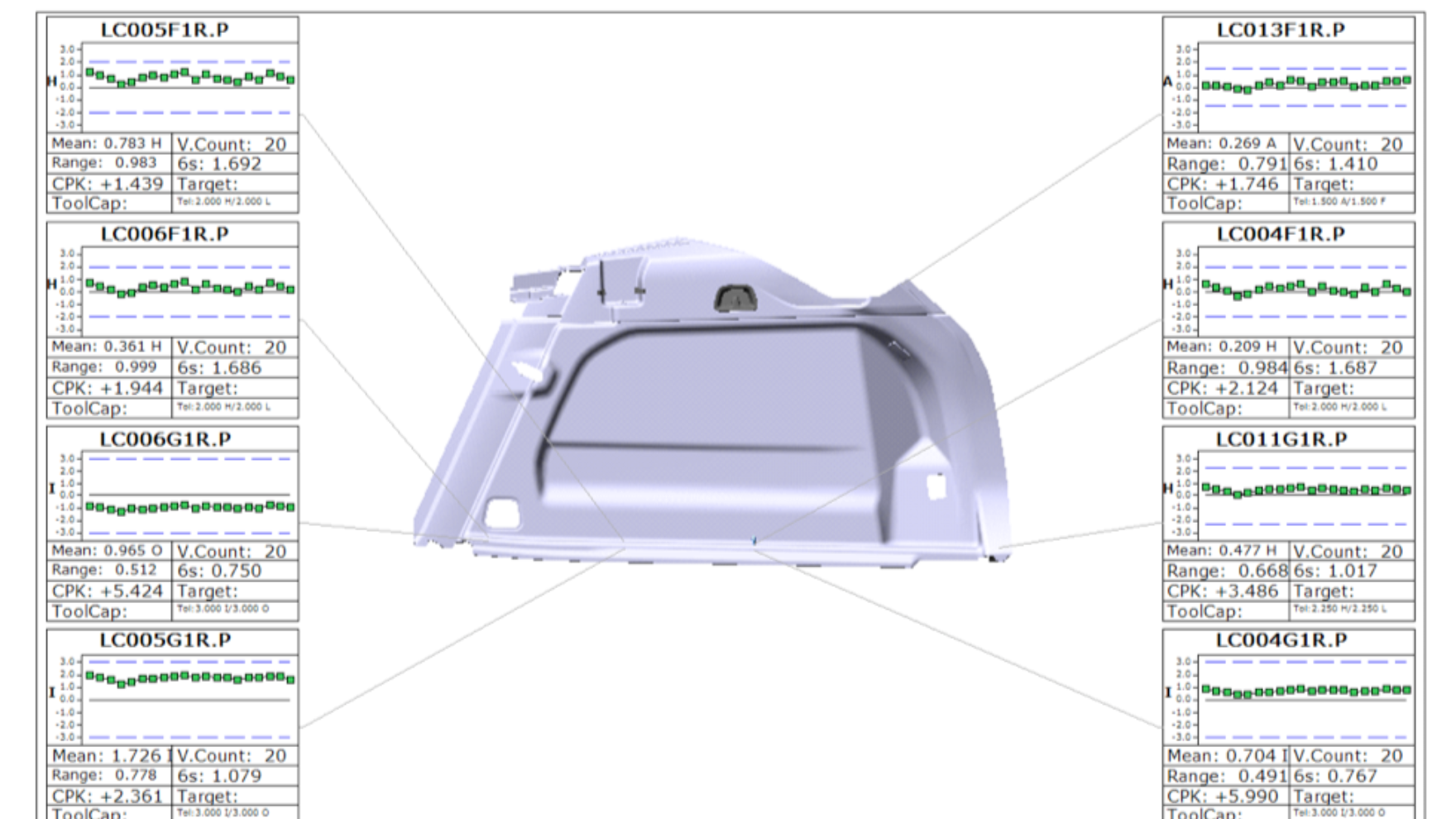

We provide reports showing repeatability, GD&T, and measurement certainty.

-

Outputs come in standard .sci or binary formats compatible with point-cloud analysis tools.

-

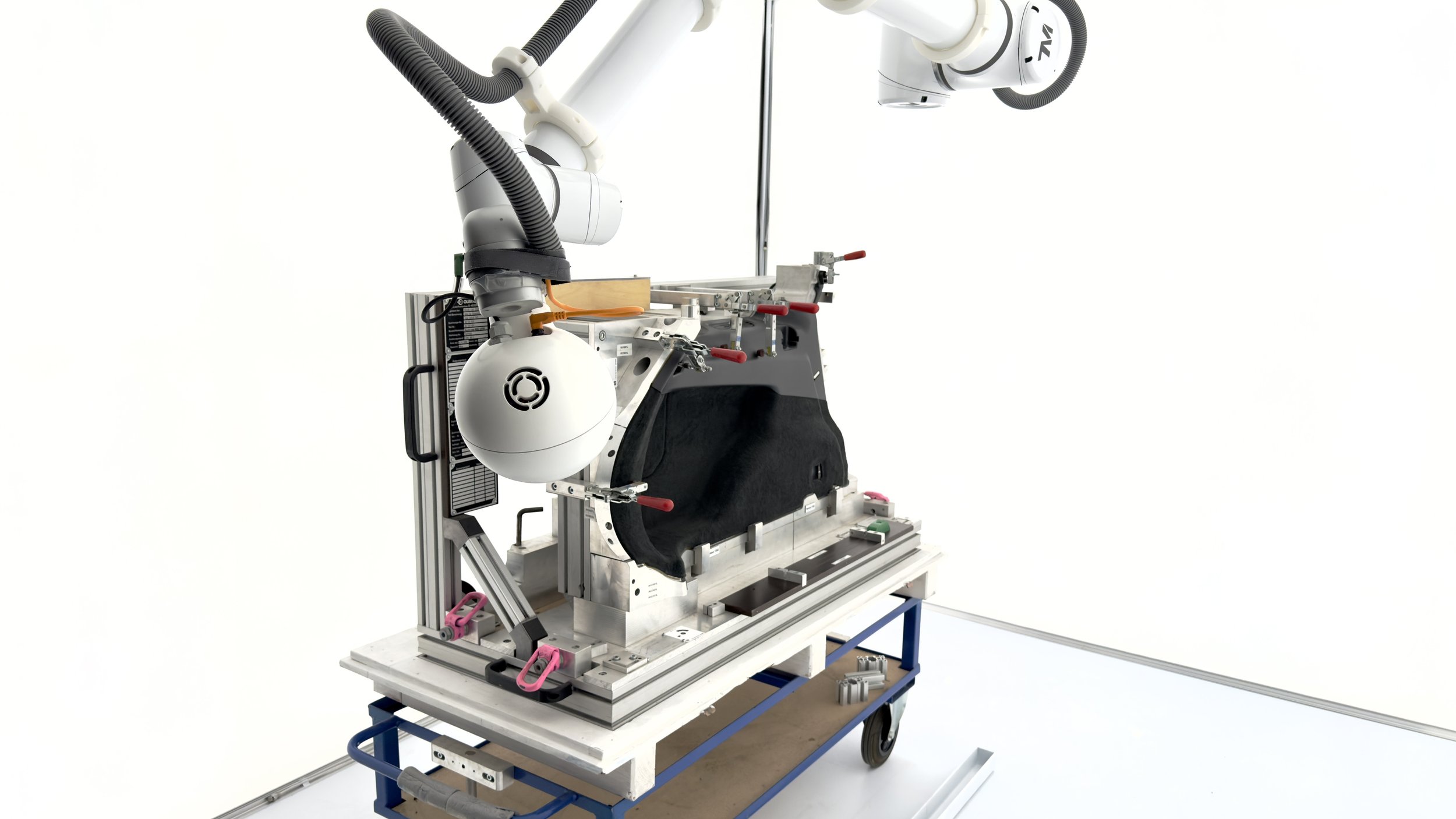

GigaScan automation is compatible with all standard PLCs and integrates seamlessly into any production line.

Proof and Reliability

GigaScan is Engineered for Precision, Trusted Without Compromise.