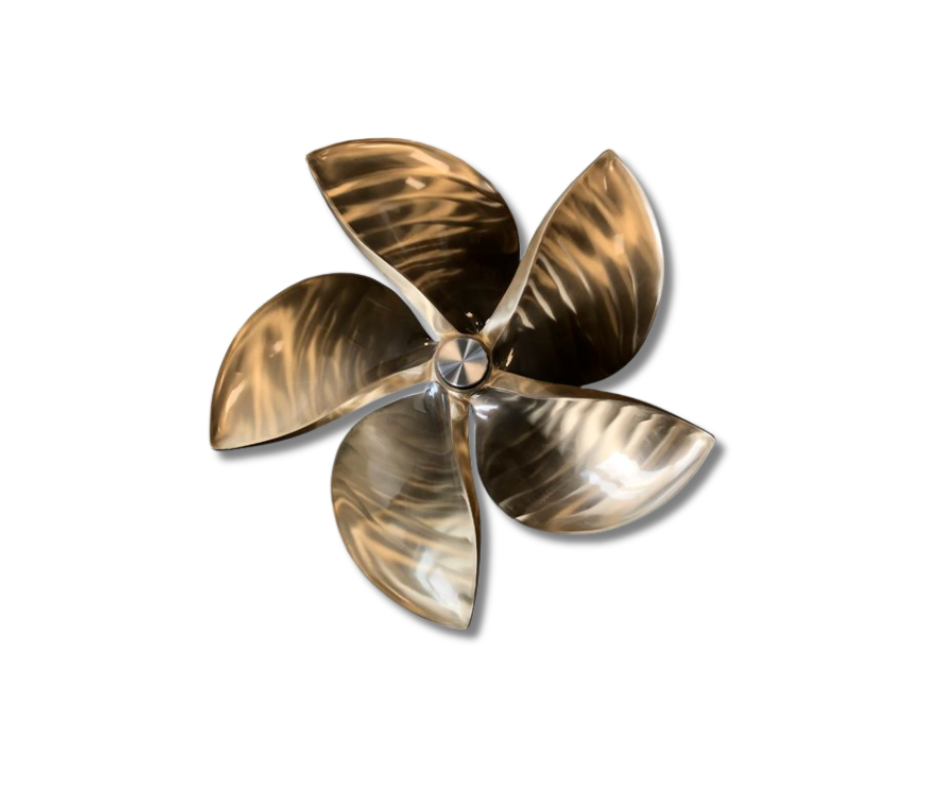

Marine Propeller Blade Inspection

A precise inspection workflow for marine propeller blades, built for shipyards, OEMs, and repair facilities that depend on accurate, consistent, and ISO-484 compliant measurement.

We manufacture a fully automated measurement system for propellers and impellers from product to analyzing.

Consistency You Can Trust

How We Can Help

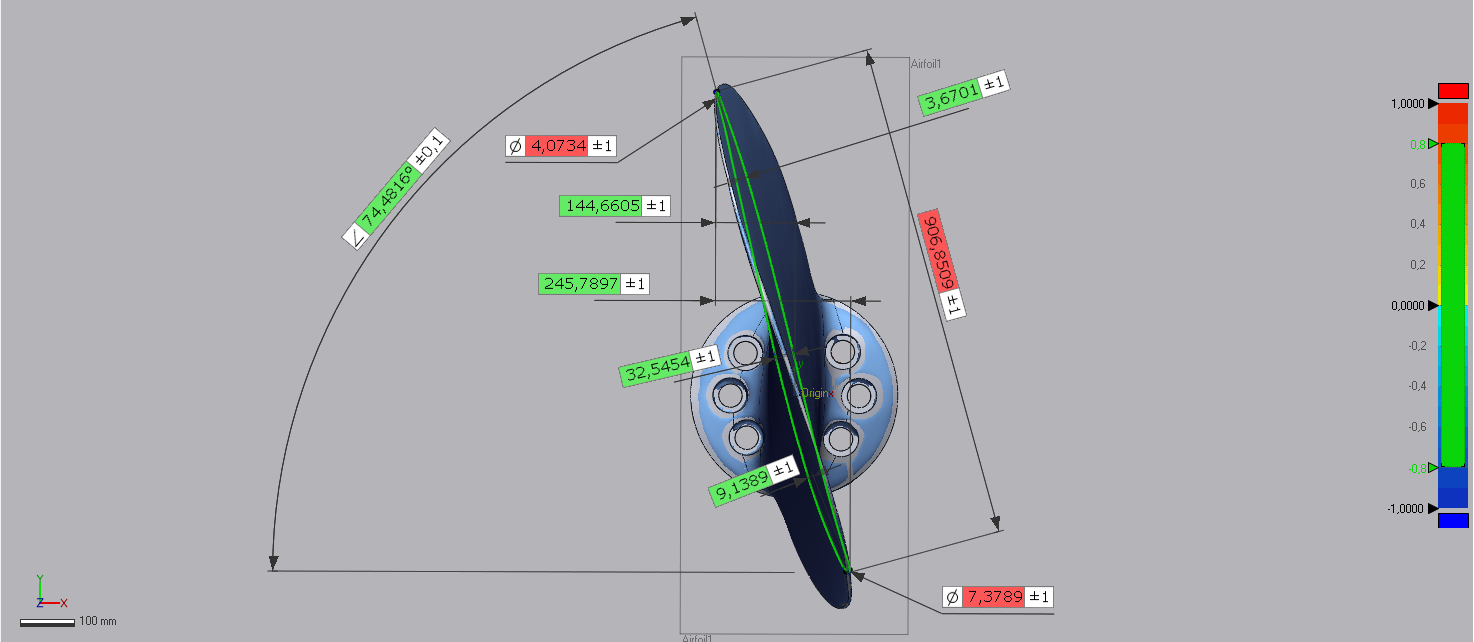

During the grinding and fairing stage, technicians shape the propeller blade to its intended hydrodynamic profile. Small deviations in twist, camber, pitch, or overall geometry can emerge at this point, and even slight inaccuracies can reduce propulsion efficiency and raise fuel consumption. By inspecting the blade during machining and blade finishing, we identify these deviations early, allowing precise corrective work and minimizing the risk of downstream rework or scrapped components.

Use Cases

What We Deliver

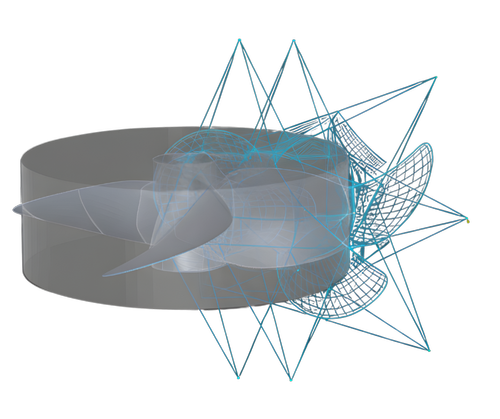

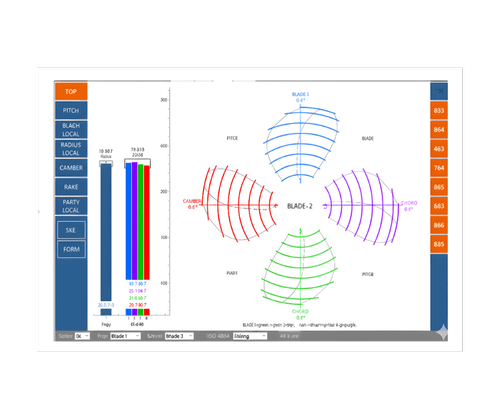

We deliver precise surface accuracy, repeatable measurement, and fully traceable digital records through a streamlined, automated inspection flow. Each scan captures complete surface coverage across pitch, leading and trailing edges, and camber, while calibrated motion paths ensure consistent, repeatable results without manual variation. Every inspection is documented in a structured digital ISO-484 report (using TrueProp) that supports quality control, compliance needs, and clear assurance for manufacturers and their customers.

The Inspection Workflow

Precision builds trust. Our GigaScan inspection system helps marine manufacturers deliver consistent quality, confident performance, and verified accuracy. Blade after blade.