Heavy foundry castings are large and complex, challenging traditional inspection in speed, repeatability, and precision. GigaScan delivers fully automated, non-contact GD&T inspection, capturing complete geometry for accurate verification of flatness, profile, position, and orientation across extensive surfaces and long feature spans.

Heavy Foundry Casting Inspection

Seeing the Entire Casting in One Measurement.

GigaScan captures the full geometry of large cast components in a single automated scan sequence. Every critical surface, edge, radius, and transition is measured as it exists on the part. The result is a complete, accurate representation of the casting that supports confident verification and downstream decision-making.

Accurate Edges, Radii, and Transitions

From Sampling to Complete Inspection

Large castings are often inspected using sampling methods due to time and handling constraints. However, sampling can miss localized defects that only appear on certain parts or regions.

High-speed automation makes full-part inspection achievable on every casting. Entire surfaces and critical features are verified consistently, improving defect detection while removing operator-dependent variability from the process.

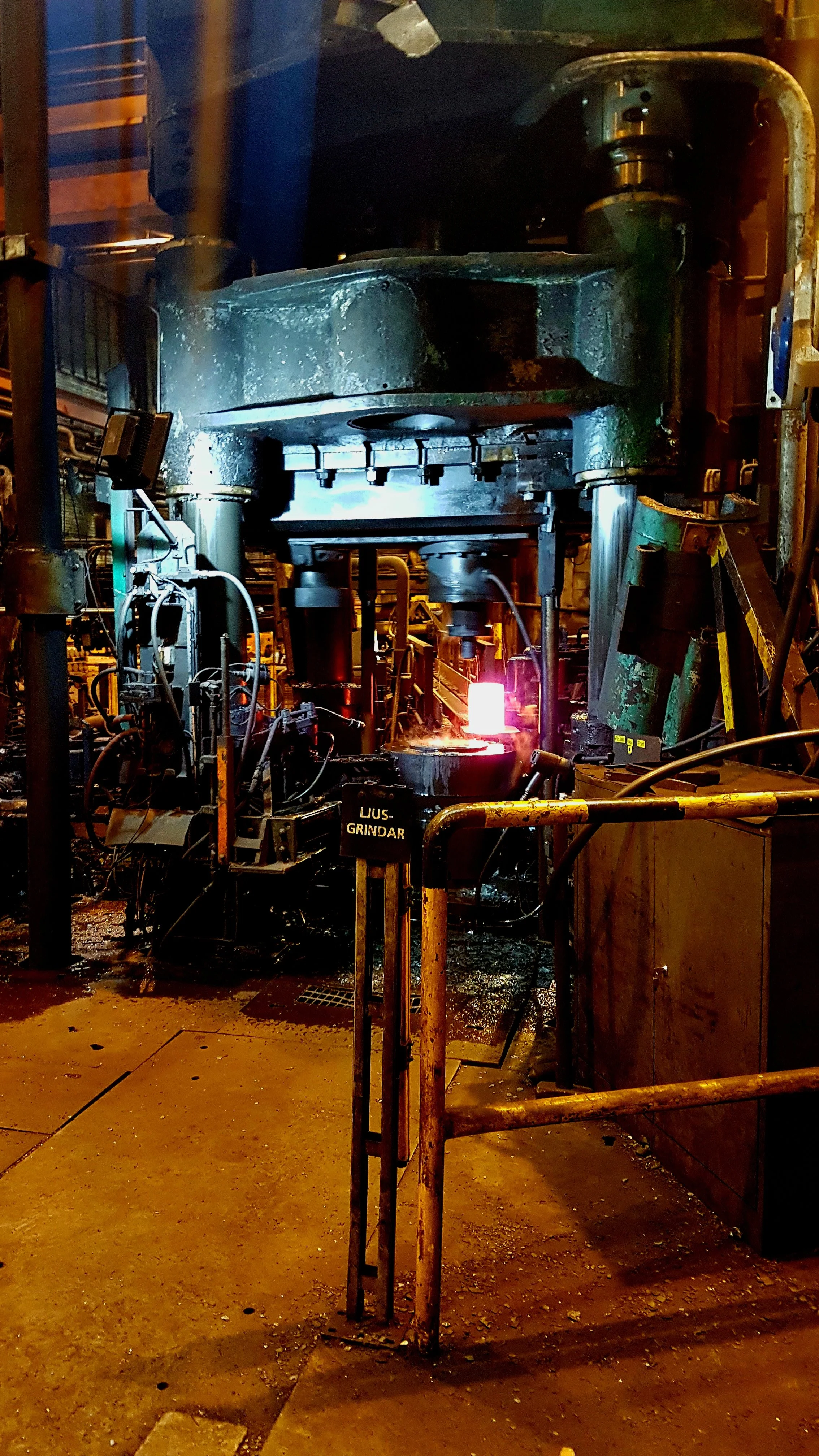

Designed for Real Foundry Conditions

Foundries experience constant vibration from cranes, furnaces, and machinery, which can reduce the accuracy of contact-based inspection. GigaScan’s non-contact inspection captures geometry quickly without physical probing, reducing sensitivity to vibration and enabling accurate measurement directly in production areas.

Large castings retain heat and can have uneven temperatures, which affect mechanical measurement systems. GigaScan’s non-contact design and fast scanning reduce sensitivity to thermal expansion, delivering consistent, reliable results directly on the shop floor.

GigaScan fits into inline or near-line foundry workflows without interrupting material handling. Results are available earlier, allowing faster detection of process drift and turning inspection into a continuous quality process.

Inline & Near-Line Integration

What Foundries Gain from the GigaScan System

Manufacturers using this approach reduce late-stage defects, limit rework, and gain tighter control over large-part quality. Full-part inspection produces standardized, auditable data that supports compliance while giving engineering and quality teams confidence in every casting delivered.

Inspect Heavy Castings with Confidence

GigaScan brings clarity, consistency, and precision to large casting inspections transforming how geometry is measured, verified, and controlled at scale.