Solving the 3D inspection for the Factory of the Future is a challenge and we at GigaScan have been developing the ‘GigaScan 3D Vision’ with the intent to create a highly flexible automated inspection system.

Based on non-contact targetless Photogrammetry, it offers improved accuracy when compared to other metrology solutions, while including all the advantages that targetless photogrammetry provides.

For a professor on Sweden’s southwestern coast, this challenge wasn’t a frustration; it was an opportunity. Over 10 years of applied research, he set out to engineer a system capable of full-field, high-resolution inspection directly on the shop floor.

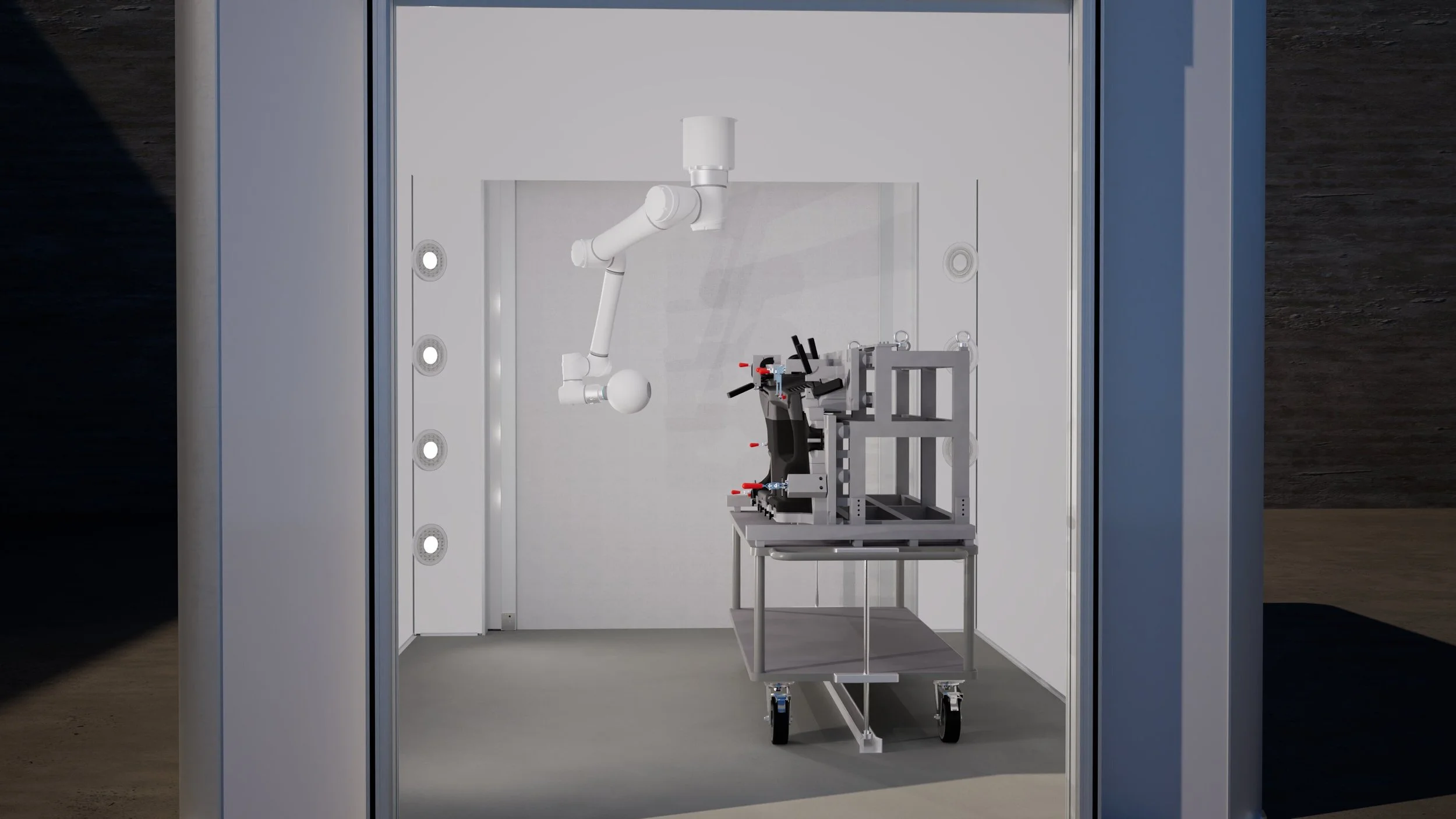

The result became something new for modern manufacturing: a surface-based photogrammetry platform that merges industrial robotics, fixed vision cameras, precision optics, and computational geometry into one automated measurement system.

A Master 3D Metrology expert specializing in non-contact measurement systems. With over 29 years of field experience, Patrik has transitioned from measuring the physical world to inventing the technology that perfects it.

GigaScan began with a simple belief: manufacturers deserve fast, accurate measurement without compromise.

Drawing inspiration from archaeology and geology; fields that reveal entire stories from surface patterns - we adapted those principles to industrial inspection. By capturing overlapping views and reconstructing 3D coordinates through triangulation, GigaScan can interpret the geometry of a fabricated part in fine detail, even in the middle of a busy production line.

Ten years of experimentation, calibration, and engineering refinement turned a research idea into a production-ready solution designed for the realities of modern manufacturing.

GigaScan Technologies AB is based in Kungsbacka, just south of Gothenburg, Sweden’s industrial heart.

Located near a long-standing hub for precision engineering, we are surrounded by a legacy of technical excellence. Scandinavian design principles guide every aspect of our approach: clarity, reliability, and solutions that simply work.

We began with a professor’s ambitious idea. Today, GigaScan is deployed to help factories solve the very problem he first identified:

If you’re facing challenges in dimensional control, inline measurement, or automating your quality assurance workflow, we’d be glad to talk.

Our technology was built for engineers; and we welcome you to explore what it can do for your factory.

Tired of “close enough”? Let’s make perfect the new normal.