Vision Beyond Precision

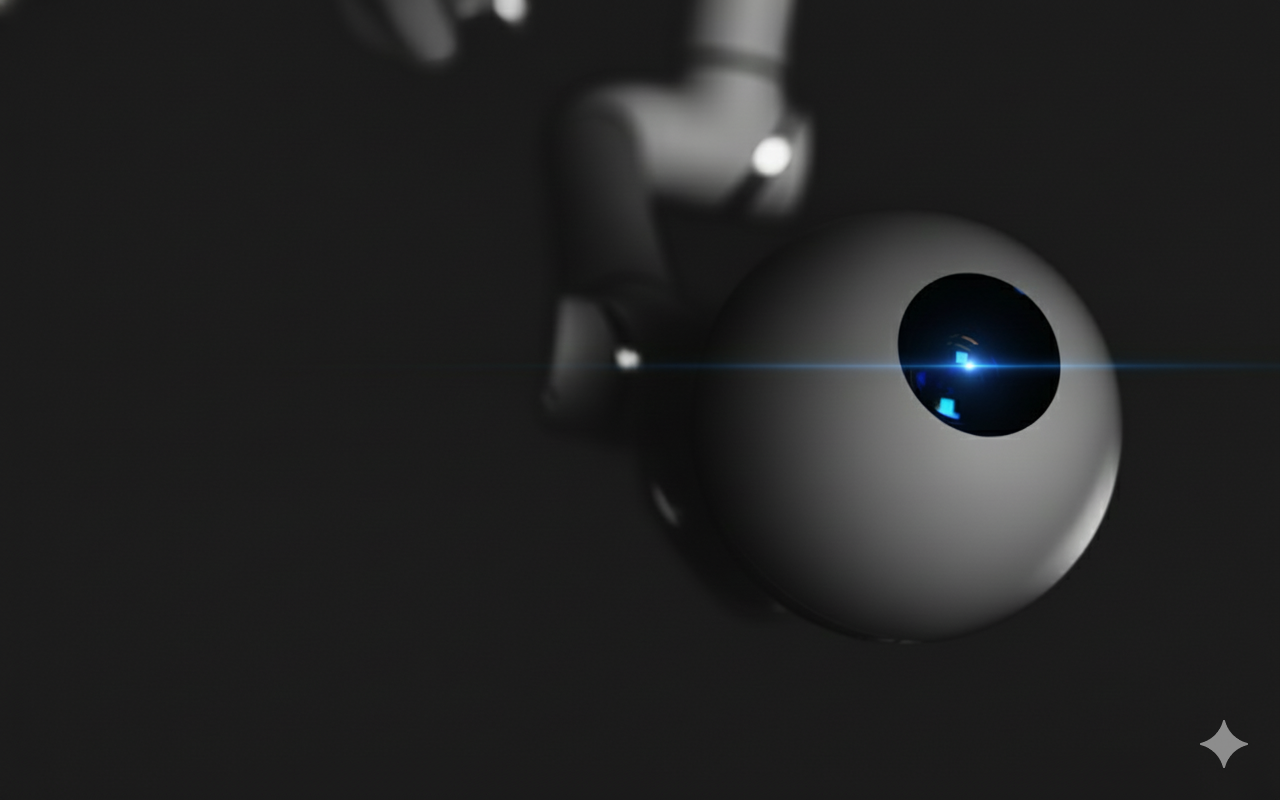

We are manufacturing the next generation of 3D vision systems for fully-automated inspection in production.GigaScan brings together high-resolution industrial cameras, collaborative robots, controlled lighting, and powerful software to capture each part with exceptional clarity. The GigaScan system ensures full coverage, enabling a single machine to handle a wide variety of components. The controlled lighting environment eliminates reflections and noise, delivering consistent and repeatable data quality.

Our software then converts this visual data into an accurate point cloud and integrates seamlessly with standard analysis tools for straightforward reporting. Using our own advanced surface photogrammetry as the core technology, GigaScan compares each surface point across multiple views to triangulate fine details producing fast, precise, and fully automated 3D data of the object, and eliminating semi-automatic or manual measurements entirely.

From tiny components to massive assemblies, every detail, every surface, every angle is captured with perfect clarity.